Proudly Canadian product.

100% recyclable

OUR

history

Our company is proud to offer a 100% Canadian and recyclable product. As an amateur hockey player for over 40 years, I have always been frustrated having to carry my two sticks, my equipment bag and my clothing bag in my car. To solve this problem, we designed a 'klip' to facilitate the transportation and personalization of the sticks

We designed a strong 'klip' using indestructible engineering resin, avoiding the problems associated with 3D printed products. Our experience in injection molding and mold making ensures the quality of our product. We are proud of this achievement and hope you enjoy using our 'klip' as much as we do.

Evolution of the 'klip' and Choice of Material

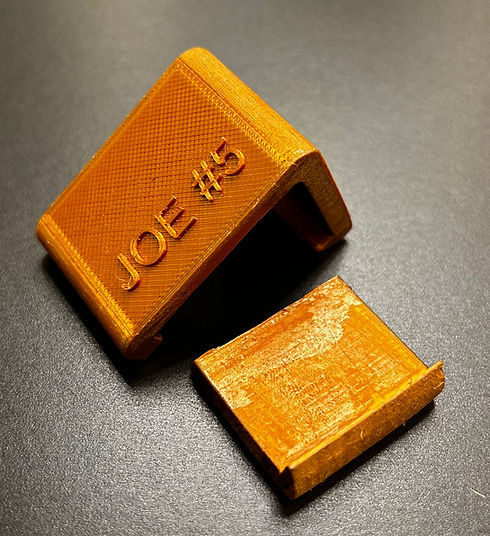

It all started with the idea of a 3D printed “klip”. We thought it would be easy to customize it to the player's preferences. We made the "klip" below with PLA Plus material. It took a few hours to produce, and we weren't sure if it was the right process for large-scale production.

Nevertheless, we were eager to test it on our sticks. To our great disappointment, after only a few manipulations, it broke into two pieces...

We then decided to make it from the strongest thermoplastic material that would still allow a little stretch (for different stick widths) without breaking. This compound will have memory/elongation without deformation. It will also need to be weatherproof, meaning it will withstand very cold temperatures as well as very hot temperatures without breaking.

Once the engineering material was selected, we purchased a block of it and machined the first sample to our exact dimensions.

From raw material

to production

After selecting the material and creating a solid sample, we collaborated with Dorval Technologies, a local steel injection mold manufacturing expert, to design a precise mold using a 5 axis CNC Milling machine. Once the mold was completed, we were ready for mass production, but we also had to provide custom tooling for our printed cards and blister packaging.

After careful evaluation, we chose Dominion Printing & Packaging for their tailor-made processes in printing, cutting, templates and tooling. Everything was then ready for production, including the molds for the blister packaging and the graphic elements